Thanks to a partnership between three companies in the BC forest industry, the Centre for Advanced Wood Processing (CAWP) at the UBC Faculty of Forestry is now home to a customized version of equipment used in sawmills throughout North America. The auto rotation conveyor, scanner, and optimization system were generously donated by Optimil Machinery, Hermary, and MPM Engineering; all local manufacturers supplying sawmill equipment worldwide.

Dr. Julie Cool, Assistant Professor in the Department of Wood Science, has spearheaded the project. “I was keen to have equipment I could use to teach sawmilling concepts and expand students’ learning experience. I also wanted to showcase Canadian manufacturers – ideally local ones,” she says. “The challenge was to find equipment that would fit our available space, since sawmilling machines are typically massive. I also didn’t want to compromise what students could learn through hands-on practical experience.”

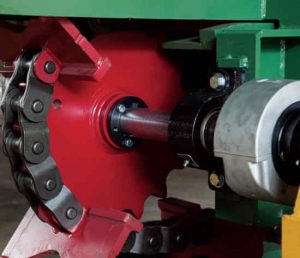

The entire assembly is 34 feet long, weighs about 16,000 pounds, and is capable of scanning logs that are 10 – 12 feet long. The auto rotation conveyor moves the raw log through the scanners that create a digital 3D image of the log, while the optimization system determines the most effective way to cut the log for best yield, highest value, or other parameters that might be programmed into the equipment.

Jason Chiu is the Managing Director of CAWP, and is excited about the potential uses of the equipment. “Students are already learning the concept of optimization of raw logs, and now they can apply that concept using this equipment. In a workplace situation, they will be able to make better recommendations for quality and value outcomes,” he says.

Optimil’s donation is the auto rotation conveyor; the piece of equipment that helps move the raw log through the scanner, before the digital image is created. Arlen Dickson manages the Service and Engineering department at Optimil Machinery.

“Like many projects, this one started with a conversation between UBC and our president, Ross Chapman,” he says. “The collaboration made sense for us because a lot of UBC forestry graduates end up working for companies where Optimil’s equipment is operated.”

Hermary, a company that provides 3D vision solutions for a variety of industries contributed the scanner. Terry Hermary is a co-partner in the business.

“Once this technology is installed in a sawmill, it’s very hard to get up close to it and see what’s actually going on. Wood chips are flying; there’s a lot of noise,” he says. “The equipment we built for CAWP allows students to operate and demystify it. Understanding scanning technology and applying the optimization concept is a real advantage for someone just entering the industry.”

The final component of the equipment is the optimization software designed by MPM Engineering, who has been creating sawmill optimization systems for over 30 years. This software helps find the optimal cutting solution for a scanned log based on the intended outcomes of the processing chain.

Rob Danzer is Director of MPM. “This equipment will allow students to improve their analytical and decision-making skills. They will take the data from the scanners, build a model that truly represents an individual log, analyze the data, and use a set of rules to find the highest value for the desired product,” he says. “And then they can figure out how to position a piece of machinery, if it were just downstream, to actually produce that product, and report on the results.”

Julie Cool sees additional potential for this equipment. “When you are scanning logs you can begin to connect what happens in the forest with what happens in the sawmill,” she says. “The scanner gives you information about curve, diameter, and so on. Since you know exactly where the log came from you can then start linking growth history to certain processing outcomes.

“Ultimately, I’d like to see us harvest a stand of trees, conduct research on it as each log goes through the processing chain, and give feedback of what we learn to the forest managers,” she says. “This new conveyor system provides a valuable link in that processing chain, and I’m really looking forward to helping students learn about it.”

The auto rotation conveyor will be a key learning component in the Sawmilling and Drying course, a third-year requirement in the Wood Products Processing program. An additional undergraduate course is being planned for 2019.

The Faculty is deeply grateful to Optimil Machinery, Hermary, and MPM Engineering for their generous contributions of valuable equipment and technology that will make a difference in applied learning and ultimate job readiness.